I met my wife at a bucolic summer camp in rural Maine when we were still teenagers. We dated all through college and graduate school, and will have been happily married for 13 years this July. My wife knows and accepts (more or less) that from March through December, when the nighttime temperatures push past the freezing mark with consistency, my love for her must be shared…with vintage brick, hand-molded terra cotta, and 19th-century limestone. That's just the way it is when your occupation is masonry restoration. And even when the mercury outside is 7 degrees like it is today, the men and I are meeting with building owners and property managers, diagnosing and troubleshooting their masonry issues.

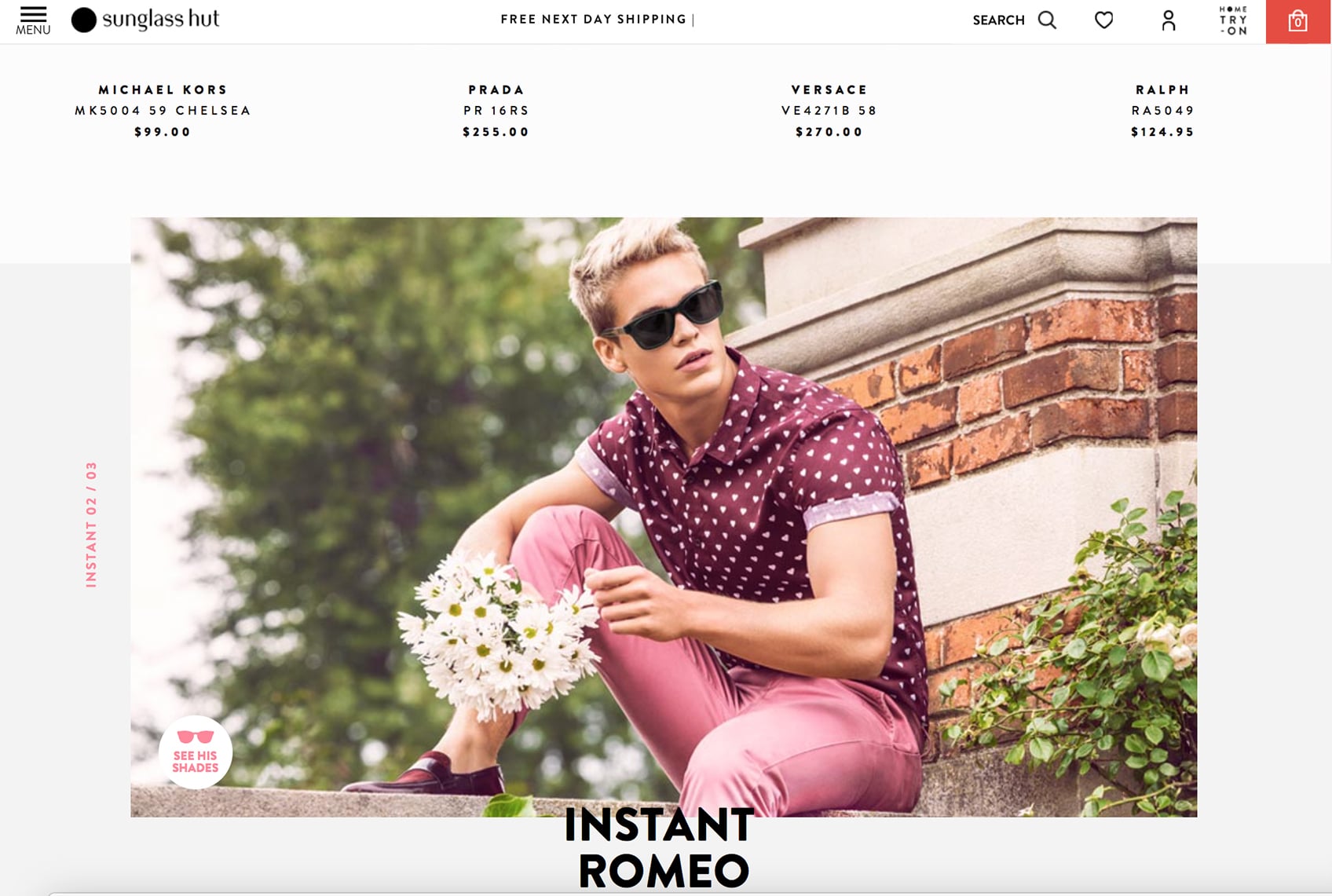

So it should really come as no surprise that when I received the above unsolicited e-mail for trendy sunglasses, my eyes quickly passed over the latest eyewear fashion (and the model in the pathetic pink and red clothing), and zoomed right in on the masonry wall in the background.

The wall looks like something constructed 100 years ago, and its formal shape is very appealing. But studying the wall more closely I realized that this brick and stone structure was a modern reinterpretation of a late 19th-century garden wall, and likely had been constructed within the last several years.

The biggest clues as to its true age were the sharp bevel cuts and crisp corners in the limestone capstones, and the size and texture of the bricks (this "modular" sized brick was not manufactured until the second half of the 20th century and its aged look has been achieved by adding a distressed red finish to an otherwise orange brick). It's a very well executed look, and nicely conveys a sense of enduring elegance.

Whether you're restoring a century old masonry structure or want to emulate the look of something from a bygone era, our licensed masons have the skills and experience to help.

Happy Valentine's Day and thank you for your support.

-Rob

Post: Happy 30th Anniversary to Frank Kruk!

Thursday February 4, 2016

We celebrated a meaningful milestone this week here at AAA-1 Masonry World Headquarters: Frank Kruk's 30th anniversary at the company!

Frank's name is synonymous with quality workmanship, integrity and patience. His expertise in this trade cannot be overstated, and he generously shares that expertise with his juniors—heck after 30 years on the job who isn't a “new comer” by comparison?

Frank started in the masonry restoration business 40 years ago and ran his own company, Fine Line, with his childhood friend Ken shortly after college (Ken's the guy in the back row of the photo, all the way on the right). Always ready for a challenge, Frank started shifting his attention to larger and more complicated masonry projects—you can read about some of these on our website—but has continued to dedicate considerable time to assisting homeowners with smaller repair projects like chimneys and stoop walls.

Frank's productivity is legendary. Despite the self-imposed workload, he is a supportive husband and father. (That's Frank in the front row, center, flanked by his wife, daughter and son, Dan, who joined the company 5 years ago).

Like the brick, stone and terra cotta he works with day in and day out, Frank is an enduring member of this company and the masonry restoration trade.

If you require masonry restoration work of the highest order, give us a call at 773-622-7300 and ask to speak to Frank. You'll be very glad you did.

Congratulations, Frank!

Post: Some Thoughts About Safety (#3 in a Series)

Wednesday January 20, 2016

This is the latest in an ongoing series of safety-related posts. See earlier entries Part 1 and Part 2.

While driving through the west side of Chicago recently, I passed by this building and was very disturbed by what I saw.

There are a number of really serious safety violations at this job site (the kinds that can lead to serious injury or death) and I thought it important to share my observations.

The first thing I noticed was the swingstage hanging from the top of the parapet wall. Even though this photo was taken from across the street, it is clear that this parapet wall is structurally compromised—look at the numerous applications of mortar applied (a cheap and short-lived method of repair), the loose and crooked capstones at the top of the building, and the green vegetation and SMALL TREE growing out of the parapet wall (about three feet below the capstones and just right of center of the swingstage)! So why in the world anyone hang a swingstage from the top of this compromised wall and expect to work safely? If this wall were to shift laterally, even slightly, the wall could collapse, and the swingstage and its occupants fall to the ground. OSHA considers any fall hazard greater than 6 vertical feet to be life-threatening, so this set-up is definitely unsafe. And what about all of those bricks falling on top of those injured workers? And what about the pedestrians walking under the swingstage, workers, and falling bricks?!? OSHA safety laws require that a swingstage be tied back to a secure immovable structure capable of handling the force generated by a fall by a factor of four in case of catastrophic failure, but I doubt those metal wall hooks at the top of the rigging are tied back to anything!

Then I noticed that this swingstage lacks a secondary braking system. Secondary braking systems are required in case the ropes from which the stage hangs (the yellow ropes on both ends of the board) fail or come loose. Without a secondary braking system the swingstage will free-fall should the ropes slip.

OSHA requires the presence of back rails to prevent workers from accidentally stepping off the swingstage. The "back rails" in this set-up appear to consist of a few pieces of 1" X 4" lumber tacked together. Completely inadequate and very unsafe! And where is the required kick board at the bottom of the stage to prevent tools and debris from falling off the stage and striking pedestrians below? And speaking of pedestrian safety, where is the required pedestrian canopy to protect passers-by from potentially catastrophic injury?

Maintaining a safe job site is of paramount importance at our company. We have a responsibility to our clients, to the public, to ourselves and to our families to safely perform our work and maintain a safe work environment. All of the masons at AAA-1 Masonry & Tuckpointing have passed Scaffolding Safety classes and maintain current certifications for fixed and swingstage scaffolding; every crew of masons is led by a foreman with over 25 years of hands-on field experience; and effective this year, every mason will have attended and passed an OSHA 10-Hour safety class.

With good training, thoughtful job site set-up and an awareness that comes from decades and decades of field experience, we mitigate work site hazards and provide you with peace of mind.

Be safe out there, and thank you for your support.

—Rob

Post: Masonry Restoration at Second Church of Christ, Scientist

Monday December 28, 2015

Keeping with the spirit of the season, I thought it appropriate to post a recently completed project we did at the lovely mid-century Church of Christ, Scientist in Evanston.

This was not our first time assisting the terrific folks at the Church, and once again the Building Committee provided invaluable assistance reserving spaces in their busy parking lot and making sure all of the different trades were properly sequenced.

After Rick & Pete Esposito at Esposito Construction completed their window restoration work, we followed on their heels and removed, primed and re-caulked over 1200 linear feet of window framing. Then we dove into rebuilding the severely deteriorated rear masonry entry.

The railings were fastened into the landings and the steps, and over the decades these metal pieces had rusted and expanded and blown apart the concrete. In addition, the design of the steps and landings encouraged water and melting snow to roll down and into the brick walls year after year, and this had taken a heavy toll on their integrity.

The walls had been tuckpointed numerous times over the decades but there was no evidence that the mortar joints had ever been ground out…so each application of mortar performed worse than the one applied prior, the mortar joints got thicker and fatter, and the wall looked very unattractive. (See below.)

We counted four separate applications of surface applied mortar on these walls but no evidence of grinding.

As the demolition of the concrete and brick progressed, we discovered significant deterioration of the load-bearing masonry walls. Through decades of benign neglect and freeze/thaw action, nearly all of the original mortar used to construct these walls had been reduced to rubble and dust (see below).

Once the concrete steps and landing were removed, we could observe the severity of the masonry wall's deterioration. Nearly all of the mortar had eroded into powder, and many of the bricks had been reduced to rubble.

With input from the Building Committee, a modified game plan was devised. All of the concrete landings and brick support walls were removed completely, and new 12" brick walls were constructed using one of our favorite workhorse bricks, the Crawford Standard (manufactured by BrickCraft in Indiana). No cinder blocks were going to be used in this project; these walls were meant to last!

We installed new support steel over the basement passageway to properly carry the weight of the top landing, and we made sure stainless steel drip edges and through-wall flashings were provided to direct residual moisture out of the walls at critical points.

The new walls were topped off with quarried Indiana limestone capstones (pre-caste capstones would have saved the Church hundreds of dollars in material costs but would never age as gracefully as genuine Indiana limestone).

After the brickwork was completed, the wall was allowed to cure for several weeks before the new concrete steps and landing were formed and poured.

Drip edges and flashing being placed on a portion of the newly rebuilt wall.

400-pound quarried limestone capstone being set in place.

Looking great!

Wishing all of you the happiest of Holidays and an exciting New Year.

—Rob

Post: Expression of Gratitude

Friday December 11, 2015

We often receive expressions of gratitude and thanks from our clients. Usually these come in the form of hand-written notes and glowing reviews on social media sites like Angie's List. We try our very best to exceed client expectations, which helps to explain why we perform hundreds of masonry restoration projects every year for condominium associations, property management companies, home owners, REITs, schools, and places of worship. Once in a while, though, the gratitude we receive really bowls us over; case in point:

This week project manager extraordinaire, Dan Kruk, returned to the office all smiles. One of his clients had been so impressed with the quality of the two-month-long parapet wall project just completed at her condominium building that she baked cookies for all of the masons! Wow! What a wonderfully personal and heartfelt expression of gratitude. (And, yes, those cookies were delicious!)

For work done right the first time, give us a call at 773-622-7300 (City) and 847-491-9700 (Suburbs). We'll do our best to make your experience a pleasant one (cookies optional).

-Rob