Long-time client, Ann Halverson, first discovered AAA-1 Masonry & Tuckpointing through the yellow pages way back in the 1990's. Impressed with the quality work she received on her then-residence in Zion and rental properties in Chicago, more than two decades later Ann still rings the office every time there is a masonry issue afoot. With a Ph.D in Chemistry and decades of apartment building ownership under her belt, Ann is no dummy! All the more reason we are proud to be considered her go-to vendor for masonry issues.

Being such loyal and vocal fan of AAA-1 Masonry & Tuckpointing, Ann received an honorary company t-shirt years ago and still wears it proudly, even when she goes abroad! Ann forwarded us this photo while taking a cultural trip to Cuba. What an honor for us. Thank you, Ann!

Post: Quality Work That Will Last For Generations

Thursday December 10, 2020

The licensed masons at AAA-1 Masonry & Tuckpointing are ready to assist you with your next restoration project.

We are as comfortable replacing shelf angles on a 110-year-old landmarked building as we are grinding and tuckpointing defective mortar joints on a 30-year-old cinder block townhouse.

For quality work that will last for generations, please call the seasoned experts at AAA-1 Masonry & Tuckpointing, Inc.

In continuous operation since 1954.

Post: The End of the Work Season Approaches

Friday November 20, 2020

Insufficient roof pitch and undersized downspouts on this rooftop penthouse allowed water to find its way into the interior spaces of this newer condominium building. The solution: Add an additional course of cinder block to the parapet walls to allow the new roof to have a more aggressive pitch. Here Sebastian and Damen start the process of raising the parapet walls (always the corners first).

The cooler weather has arrived and with it an acknowledgement that the number of work days remaining in the season is dwindling. Mortar starts to freeze around 26°F, so at this time of year we study the weather forecasts more than usual to ensure work conditions are safe. If it is too cold for the mortar to cure properly, then we won’t work.

Even though AAA-1 Masonry & Tuckpointing will not work when temperatures are too cold for mortar to cure properly, surprisingly there is no law against it. So, even when the nighttime temperatures are expected to drop well below 26 degrees, if it is sunny during the day you’ll commonly see construction projects in full swing with mortar being mixed and masonry repairs being performed. More often than not, the property owner has no idea mortar requires many days to cure and freezing fresh mortar will lead to poor performance and premature failure.

Although the outdoor work will soon come to a close, we remain very busy meeting with property managers, engineers and home owners to discuss projects for the spring. Should you require a free consultation with one of our licensed masons, please do not hesitate to call or e-mail.

Happy Thanksgiving!

Post: Exceptional Masons Produce Exceptional Masonry Work

Thursday September 24, 2020

The owner of this neglected commercial building stripped the 1950’s cream-colored brick facade down to the ground and created a red brick beauty with a nod to 19th century building methods and aesthetics.

The limestone beltlines, hand-carved address stone, 16”-thick true masonry walls (sans cinder block), and arched window headers with hand-molded radial bricks combine to create a real show-stopper!

On the inside, exposed ceiling joists, sandblasted Chicago common brick, and quarter-sawn oak office partition walls with double-glue chip glass complete the vision.

Let AAA-1 Masonry & Tuckpointing's licensed masons assist you with your next dream project.

In continuous operation since 1954.

Before:

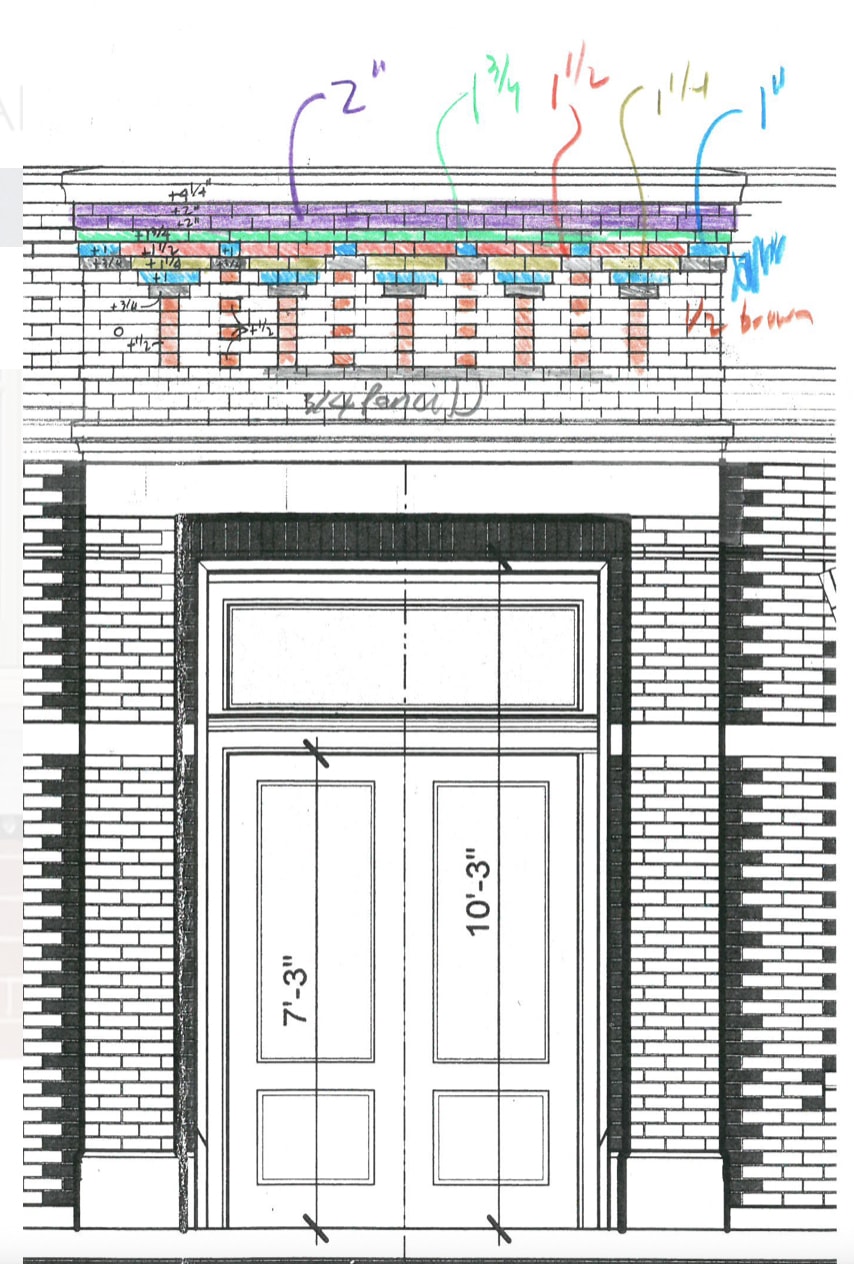

During #1: Architectural drawings of the parapet wall detail to be constructed.

During #2: Full size mock-up of the parapet wall detail is constructed in the shop to confirm feasibility.

After:

Post: Changing of the Season

Sunday March 8, 2020

Installation of heavy-duty vinyl tarpaulins to an unobstructed south-facing wall in Hyde Park that a previous owner had parged (i.e., skim coated) decades earlier with mortar. Unfortunately the parge coating was insufficient to prevent moisture from infiltrating the underlying 150-year-old brick wall and damaging the interior plaster work. The installation of the tarps stopped new damaged from occurring and allowed the brick and plaster work to dry out.

Although it is still technically winter, one would be hard pressed to believe it by looking at the outdoor thermometer.

Daytime temperatures have been hovering comfortably in the 50s for a few days now and, more importantly, the nighttime temperatures have been above freezing with consistency. (As masonry restorationists, we care most about nighttime temperatures because mortar that freezes at night will neither cure correctly nor perform properly.)

During the winter months when it is too cold for mortar to cure correctly, the masons at AAA-1 Masonry & Tuckpointing spend many days affixing heavy-duty vinyl tarps to masonry walls as a means of stopping wind-driven snow and sleet and rain from infiltrating masonry walls and causing all kinds of grief for building occupants.

Our tarps are 18 ounce heavy-duty vinyl, made in America, and will not rip or shred for decades. (We know this to be true because we have had tarps installed on some buildings for 20 years with no issues whatsoever.)

Heavy-duty vinyl tarps prevent wet weather events from wreaking havoc on your bricks, split-face blocks and other masonry substrates by providing a physical barrier between Mother Nature weather and your walls.

Occasionally owners and property managers need time to build up capital reserves in order to tackle a larger masonry project. Vinyl tarps stop the clock and allow for the build up of reserves without the masonry incurring additional damage. Typically, the cost of affixing a heavy-duty vinyl tarp to a defective masonry wall is a small fraction of the cost of performing the actual masonry repairs.

If you think your property could benefit from the installation of American made heavy-duty vinyl tarpaulins by our team of licensed masons, please reach out to us for a free quote.

Thank you for the opportunity to be of service!

-Rob